Xinyang Silicomeric (Shanghai) Semiconductor Co., Ltd. (hereinafter referred to as "Xinyang Silicomeric Semiconductor"), a joint-stock enterprise of UniTTEC, was established by Shanghai Xinyang Semiconductor Materials Co., Ltd. and Guimisixin Semiconductor Technology (Shanghai) Co., Ltd in April 2016. The registered capital of the company is RMB 78 million, with a workshop area of 3,000 square meters, a 1000-square-meter clean workshop and an industry-leading professional laboratory of semiconductor electroplating process. The company has established an industry-leading integrated process service platform of wafer-level wet-process electroplating equipment, wet process equipment & chemical liquids of semiconductor.

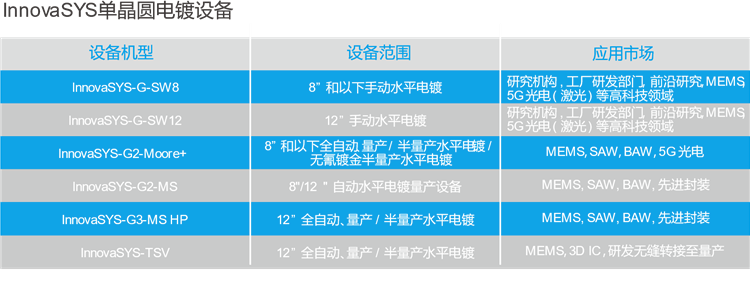

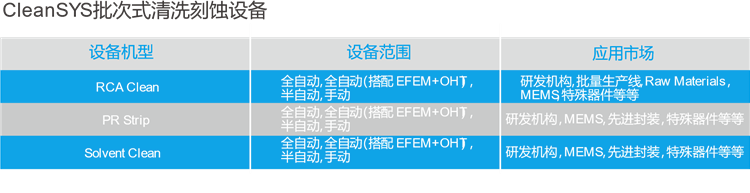

The company focuses on the development, production, sales and service of semiconductor wet process electroplating equipment and related wet process equipment. The main products include InnovaSYS single wafer electroplating equipment, CleanSYS batch cleaning and etching equipment, etc.

Service Cases:

Beijing Youyan, building of a whole cleaning line

Shanghai Xin’ao, cleaning process upgrade

Nanjing Guosheng, cleaning process upgrade

Zhejiang Jinruihong, cleaning process upgrade

Luoyang Mesker, cleaning process upgrade

Research Institute No. 46, CETC, cleaning process upgrade

TI CFAB DNS 820.C installation and equipment module transformation

TI CFAB DNS 820.L installation and equipment module transformation

TI CFAB SCP 9400 installation and modification

Design and modification of TI CFAB (43 sets) automatic CO2 detection/fire extinguishing system

BCD 12 wet equipment installation and modification, including KAIJO, DNS, SEMITOOL

GSMC Akrion/SCP 9400 pre-clean wet equipment installation/retrofit

GSMC Akrion/SCP 9400 organic solvent wet process equipment installation/retrofit

BCD pure water heating system installation and transformation

Design and modification of Kaijo and DNS automatic CO2 detection/extinguishing system for TSMC (9 sets)

SIMBCD "5 upgrade to 6" wet equipment project of the whole line

IMECAS 5 "upgrade to 6" whole-line wet equipment project

Delivery of 26 sets of wet process equipment to China Resources Crystal Core 6"

Shanghai Beiling 6" whole-line wet process equipment project

SMIC Chengdu (TI) 8" line transfer project

Tech Semiconductor mobile project

Wet process equipment transfer project by TSMC from Atmel (England)

TSMC upgrade of DNS wet method equipment SOM to SPM equipment module

Design and renovation of SK Hynix WuXi (4 sets) automatic CO2 detection/fire extinguishing system

Installation and process debugging of ALL THE E200 wet process equipment of SMIC FAB1

CSMC KAIJO organic solvent wet process equipment megasonic machine heater modification

SKY SILICON DNS 820.C equipment module transformation

Transfer and process debugging project of 7 12-inch JET BW3000 PR strips of SMIC

3 12-inch JET BW3000 PR Strip refurbishment machines in Silan

GSMC SEMITOOL organic-solvent wet equipment installation/automatic CO2 fire extinguishing system

浙公网安备33010802004479号

浙公网安备33010802004479号